THE SMART WEIGHING MAT

Discover the collaboration between EFI Automotive Service and the French start-up Altaroad.

The project and its context

Cécile Villette, Bérengère Lebental and Rihab Jerbi are the three co-founders of the start-up Altaroad, which was created to improve the sustainability and safety of road infrastructure. To this end, the company has formed a partnership with the École Polytechnique, the CNRS and the Gustave Eiffel University to develop a machine learning platform and a sensor network capable of collecting data in real time on the vehicles accounted by the system.

Their solution, based on the TopTrack weighing belt, enables better monitoring of waste on a construction site and was the winner of the European Innovation Council competition in July 2020. Concurrently, a digital solution – called DigiTrack and connected to the government’s TrackDéchets platform – has been developed to ensure the traceability of the data collected by TopTrack.

The project in video

Project milestones

September 2020

INITIAL CONTACT PHASE

The start-up contacted our teams through the Group’s industrial accelerator – Axandus.

October 2020

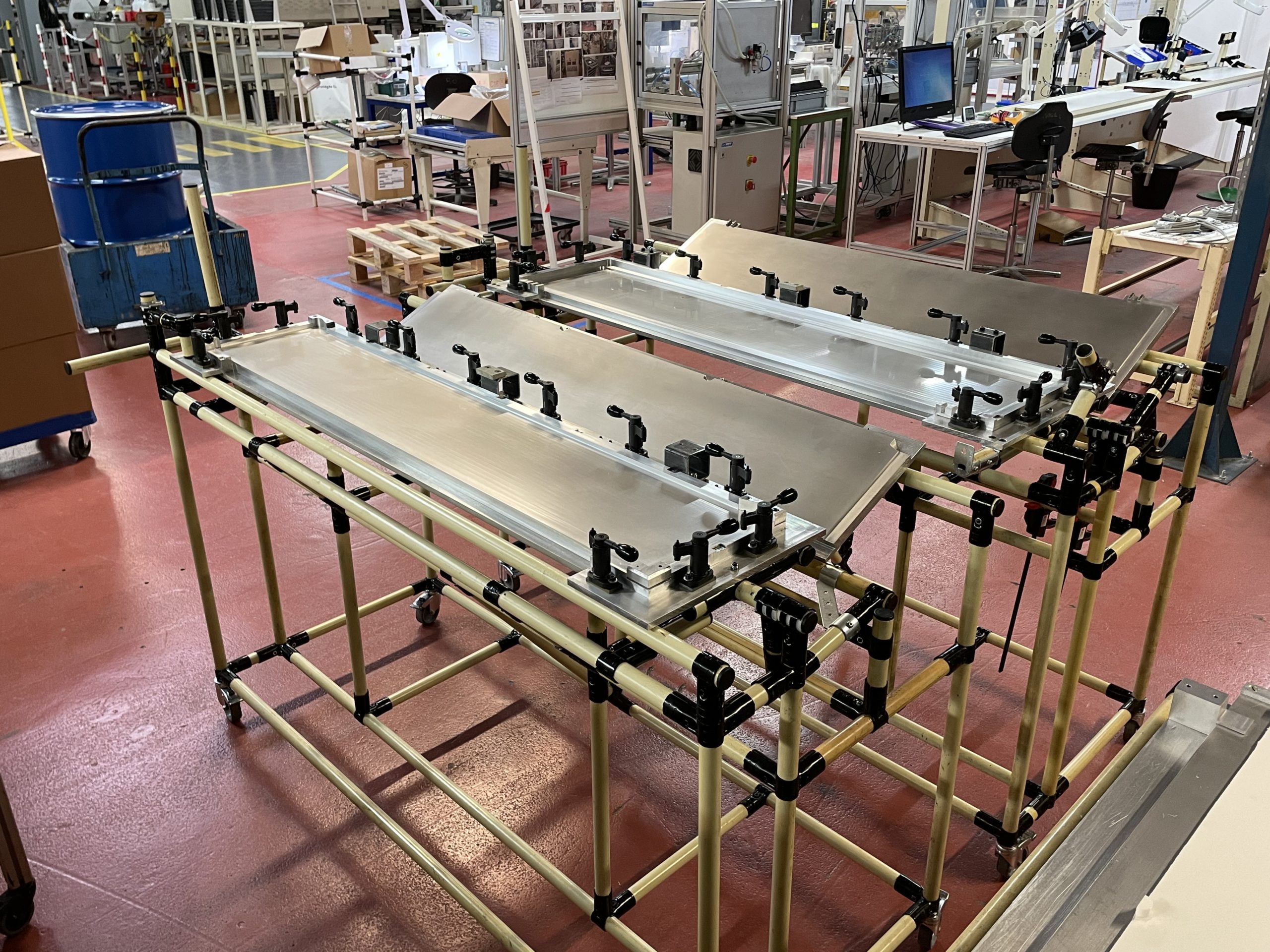

PRODUCTION OF PROTOTYPES ON A LINE DEDICATED TO THE PROJECT

Our teams assembled around ten systems to test the product in real conditions.

November 2020 – March 2021

MANUFACTURING PROCESS IMPROVEMENT PHASE

During this period, the manufacturing process was optimised to make the project more easily industrialisable.

September 2021

PRODUCTION OF NEW TOOLS AND PROTOTYPES

After tooling modifications following the previous stage, the teams once again produced prototypes.

December 2021 – January 2022

PRODUCT IMPROVEMENT PHASE

The teams and the start-up worked to optimise the weighing system’s sensitivity.

February 2022

CUSTOMER TESTING PHASE

The teams went to the customer’s premises to carry out a series of tests.

September 2022

DISCUSSIONS WITH THE START-UP ABOUT THEIR SECOND GENERATION OF MATS

InTrack, the new weighing system integrated under the asphalt was in the final phase of development.

December 2022

AWARD OF A FINANCIAL GRANT

The Altaroad teams submitted an application to obtain subsidies to make further progress on their R&D. After several weeks of waiting, the teams received a favourable response.

January 2023 – Now

DEVELOPMENT OF THE INTRACK SOLUTION

For over a year now, the start-up's teams have been focusing on developing their solution, InTrack. It is supposed to be installed under roads, and it now includes an additional problem.

Our added value

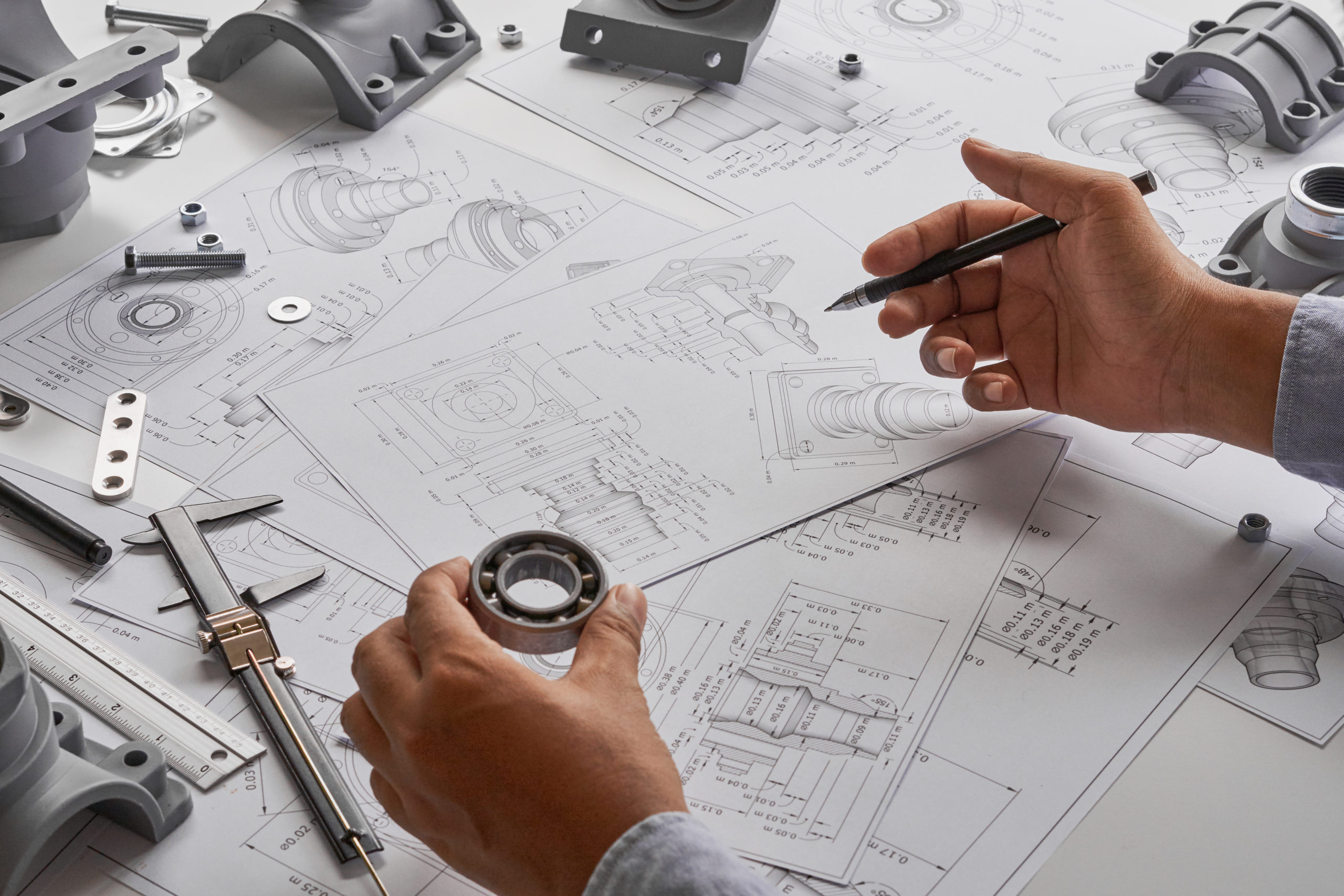

Within the framework of this project, one of EFI Automotive Service’s first in the support of innovative companies, we were able to offer Altaroad our expertise in the following areas:

- Setting up a production line: 100 m² dedicated to the production of weighing systems.

- Implementation of a double industrial support, both on the product and on the manufacturing process.

- Management of the supply of raw materials for the prototypes and suggestions for the optimisation of certain components to improve the performance and assembly of the product.

This project illustrates that our teams can perfectly support an innovative start-up/company that has already designed its first prototypes. The support offered is therefore adapted to the degree of progress of each project.

Project key figures

10%

reduction of transport costs thanks to TopTrack

0

paper and contact to use the solution

-7%

impact on CO2 emissions

100%

of reliability for the capture of number plates

Project key figures

10%

reduction of transport costs thanks to TopTrack

paper and contact to use the solution

-7%

impact on CO2 emissions

100%

of reliability for the capture of number plates

Are you interested in our support?

Do you have a project?

Safehear

THE HEARING PROTECTION OF THE FUTURE

Discover the collaboration between EFI Automotive Service and the French start-up Safehear.

The project and its context

The Safehear adventure began with the response to a constraint: to enable employees working in noisy environments (industrial sites) to communicate without latency and without risk of hearing loss. Héléna Jérome and Antoine Kuhnast, co-founders of the French start-up, hired partners from the major players in the in-ear market and research institutes to develop their solution. The outcome was a Made in France product named Louis; it is now promoted by a dynamic technical and commercial team.

The project in video

Project milestones

October 2021

INITIAL CONTACT PHASE

The start-up contacted our teams through the Group’s industrial accelerator – Axandus.

May 2022 – November 2022

PROTOTYPING

The teams start the design phase of the prototypes for the start-up.

December 2022

PROPOSAL OF SUPPORT FOR THE CONTINUATION OF THE PROJECT

Our teams have already proposed to the start-up to go further, by suggesting improvements for the second version of Louis.

March 2023

END OF COLLABORATION WITH OUR COMPANY

With no further need for our services (prototyping), the Safehear teams decided to end their industrial collaboration with our company.

Our added value

Within the framework of this project, one of EFI Automotive Service’s first in the support of innovative companies, we were able to offer Safehear our expertise in the following areas:

- Design and production of prototypes (80 planned by 2023)

- Provision of a 30 m² pressurised room allowing the teams to work in a controlled environment

KEY FIGURES OF THE PROJECT

20

prototypes made to date

100 dB

maximum sound volume in which Louis can operate effectively

29 dB

of maximum noise level reduction

10 h

of autonomy

15 m

maximum range between two users

30 gr

Louis’ weight

2

years of research and development to create Louis

3 h

required for a complete recharge

KEY FIGURES OF THE PROJECT

20

prototypes made to date

100 dB

maximum sound volume in which Louis can operate effectively

29 dB

of maximum noise level reduction

10 h

of autonomy

15 m

maximum range between two users

30 gr

Louis’ weight

2

years of research and development to create Louis

3 h

required for a complete recharge

Are you interested in our support?

Do you have a project?