THE SMART WEIGHING MAT

Discover the collaboration between EFI Automotive Service and the French start-up Altaroad.

The project and its context

Cécile Villette, Bérengère Lebental and Rihab Jerbi are the three co-founders of the start-up Altaroad, which was created to improve the sustainability and safety of road infrastructure. To this end, the company has formed a partnership with the École Polytechnique, the CNRS and the Gustave Eiffel University to develop a machine learning platform and a sensor network capable of collecting data in real time on the vehicles accounted by the system.

Their solution, based on the TopTrack weighing belt, enables better monitoring of waste on a construction site and was the winner of the European Innovation Council competition in July 2020. Concurrently, a digital solution – called DigiTrack and connected to the government’s TrackDéchets platform – has been developed to ensure the traceability of the data collected by TopTrack.

The project in video

Project milestones

September 2020

INITIAL CONTACT PHASE

The start-up contacted our teams through the Group’s industrial accelerator – Axandus.

October 2020

PRODUCTION OF PROTOTYPES ON A LINE DEDICATED TO THE PROJECT

Our teams assembled around ten systems to test the product in real conditions.

November 2020 – March 2021

MANUFACTURING PROCESS IMPROVEMENT PHASE

During this period, the manufacturing process was optimised to make the project more easily industrialisable.

September 2021

PRODUCTION OF NEW TOOLS AND PROTOTYPES

After tooling modifications following the previous stage, the teams once again produced prototypes.

December 2021 – January 2022

PRODUCT IMPROVEMENT PHASE

The teams and the start-up worked to optimise the weighing system’s sensitivity.

February 2022

CUSTOMER TESTING PHASE

The teams went to the customer’s premises to carry out a series of tests.

September 2022

DISCUSSIONS WITH THE START-UP ABOUT THEIR SECOND GENERATION OF MATS

InTrack, the new weighing system integrated under the asphalt was in the final phase of development.

Our added value

Within the framework of this project, one of EFI Automotive Service’s first in the support of innovative companies, we were able to offer Altaroad our expertise in the following areas:

- Setting up a production line: 100 m² dedicated to the production of weighing systems.

- Implementation of a double industrial support, both on the product and on the manufacturing process.

- Management of the supply of raw materials for the prototypes and suggestions for the optimisation of certain components to improve the performance and assembly of the product.

This project illustrates that our teams can perfectly support an innovative start-up/company that has already designed its first prototypes. The support offered is therefore adapted to the degree of progress of each project.

Project key figures

10%

reduction of transport costs thanks to TopTrack

0

paper and contact to use the solution

-7%

impact on CO2 emissions

100%

of reliability for the capture of number plates

Project key figures

10%

reduction of transport costs thanks to TopTrack

paper and contact to use the solution

-7%

impact on CO2 emissions

100%

of reliability for the capture of number plates

Are you interested in our support?

Do you have a project?

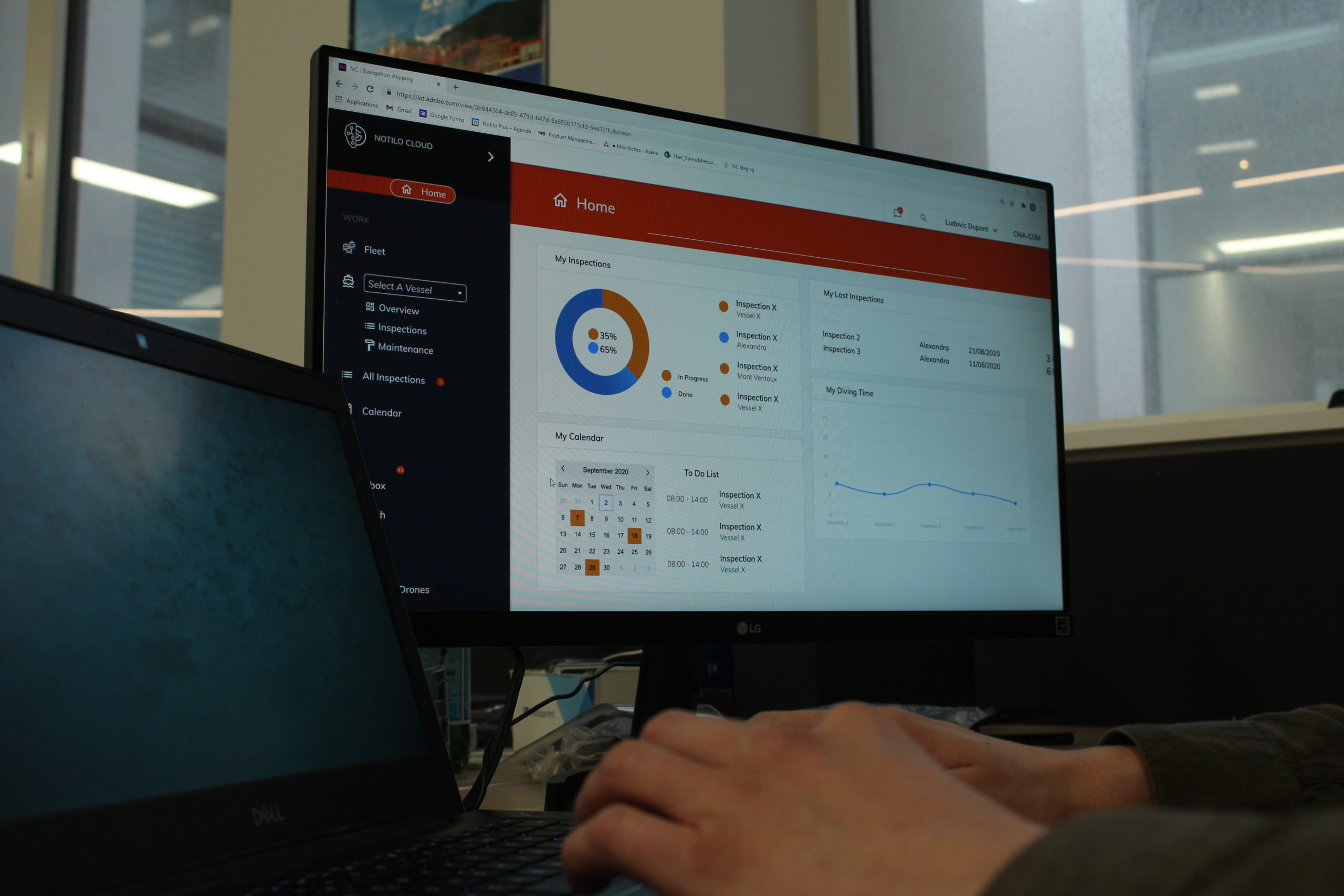

Delair Marine

THE SMART UNDERWATER DRONE

Discover the collaboration between EFI Automotive Service and the French start-up Delair Marine.

THE PROJECT AND ITS CONTEXT

The story of Delair Marine begins with a group of passionate divers and drone experts who, during their explorations, had the idea to design an autonomous underwater drone. To turn this idea into reality, they recruited a multidisciplinary team of embedded software developers, mechatronics experts, innovative marketers… and of course, EFI Automotive Service, through Axandus – the EFI Automotive Group’s industrial accelerator.

This first offer, aimed at recreational diving and yachting, was successful and the company has now extended its range with a solution aimed at professionals and scientists. In addition, it is now possible to collect and analyse the data gathered by these drones through Delair Marine’s Cloud service. Possible applications range from coastal infrastructure analysis to ship hull inspection and search and rescue operations.

Formerly Notilo Plus, the start-up was acquired at the end of 2022 by Delair – an international provider of high-performance drone-based solutions – and renamed Delair Marine.

The project in video

PROJECT MILESTONES

April 2018

INITIAL CONTACT PHASE

The start-up contacted our teams through the Group’s industrial accelerator – Axandus.

September 2018

REDESIGN AND QUALIFICATION OF THE PRODUCT

The product requires some design adjustments in order to be industrialized more easily.

From September 2018 to March 2019

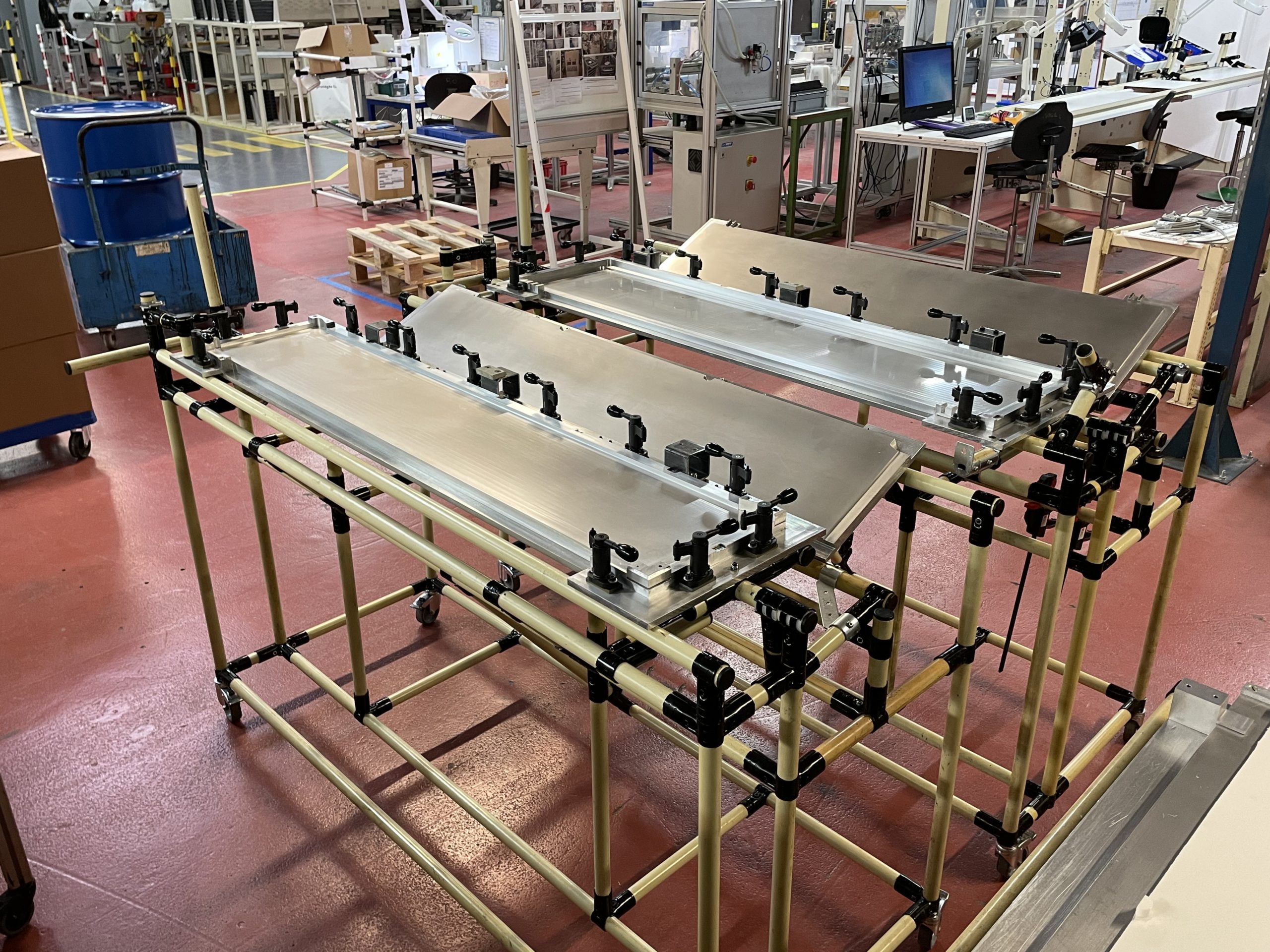

STUDY AND DEVELOPMENT OF THE PRODUCTION LINE

The teams design and operate an assembly line of 120 m² common to the different products of the start-up.

April 2019

START OF PRODUCTION PHASE 1

After a conclusive test phase, the teams officially launch the production of the underwater drone, iBubble.

January 2020

START OF PRODUCTION PHASE 2

After adapting the line, the teams officially launch the production of the underwater drone, Seasam in addition to iBubble.

From January 2020 to December 2022

MAINTAINING THE PARTNERSHIP AND PRODUCTION

The teams maintain a close relationship with those of the start-up and are currently working on projects that will see the light of day soon, in parallel with ongoing production.

From January 2023 to date

ACQUISITION OF THE START-UP

After the acquisition of the start-up, the new teams exchange with those of our company to consider the future of this collaboration.

OUR ADDED VALUE

Within the framework of this project, one of the first of EFI Automotive Service, in the accompaniment of innovative companies, we were able to propose to Delair Marine these various know-how:

- Standardization of the product, particularly in terms of screwing, in order to facilitate assembly operations and limit the risk of error

- Setting up a flexible multi-reference island: 140 m² dedicated to the production of these underwater drones, acquisition of new skills for our teams via this project (multi-layer electronic assembly, handling of aspect parts, waterproofing, etc.)

- Management of deliveries and after-sales service: implementation of the entire supply chain up to direct shipment to customers (individuals and professionals worldwide – including customs management)

KEY FIGURES OF THE PROJECT

440

iBubble EVO manufactured

90

Seasam manufactured

120 m²

of assembly line dedicated to this project

3

specially trained operators on the production line

100 m

of maximum depth

4

hours of underwater autonomy

7

number of engines equipping the drones

2

solutions proposed by the start-up Delair Marine

KEY FIGURES OF THE PROJECT

440

iBubble EVO manufactured

90

Seasam manufactured

120 m²

of assembly line dedicated to this project

3

specially trained operators on the production line

100 m

of maximum depth

4

hours of underwater autonomy

7

number of engines equipping the drones

2

solutions proposed by the start-up Delair Marine

Are you interested in our support?

Do you have a project?

Hoverseen

THE AUTOMATIC VIDEO SURVEILLANCE DRONE

Discover the collaboration between EFI Automotive Service and the French start-up Hoverseen.

The project and its context

Aerial drones have many advantages: they are light, fast, always available and their prices have become quite reasonable. They therefore make it possible to observe an area at any time, and without the need to put a physical person at risk. Applications can be surveillance rounds, land use analysis or monitoring of delivery movements…

Until now, these drones have exclusively been remote controlled, sometimes through a particularly complex interface. Hoverseen’s proposed solution integrates a control and recharging base that allows the pre-programming of flight plans, which the drone will then carry out in complete autonomy. In addition, it is equipped with a weather station that can determine whether the flight conditions are favourable. The drone can also take off and land without human intervention.

The project in video

Project milestones

July 2021

INITIAL CONTACT PHASE

The start-up contacted our teams through the Group’s industrial accelerator – Axandus.

September 2021

TEAM TRAINING AT HOVERSEEN

The teams visited the client for a week to learn about the product and acquire the necessary knowledge.

From October 2021 to date

PROTOTYPING

The teams start the design phase of the prototypes for the start-up.

Our added value

Within the framework of this project, one of EFI Automotive Service’s first in the support of innovative companies, we were able to offer Hoverseen our expertise in the following areas:

- Design and production of prototypes: on this occasion, our teams managed to reduce the base’s assembly time from 5 to 3 days

- Provision of a 30 m² pressurised room allowing the teams to work in a controlled environment

KEY FIGURES OF THE PROJECT

50 kg

weight of the control and recharging base of the drone

50 km/h

maximum speed of the drone

25 min

maximum autonomy

585 gr

weight of the drone

KEY FIGURES OF THE PROJECT

50 kg

weight of the control and recharging base of the drone

50 km/h

maximum speed of the drone

25 min

maximum autonomy

585 gr

weight of the drone

Are you interested in our support?

Do you have a project?

PALO IT

LE DISPOSITIF ANTI-CONTREFAÇON

Découvrez la collaboration entre EFI Automotive Service et l’entreprise française, PALO IT.

Le projet et son contexte

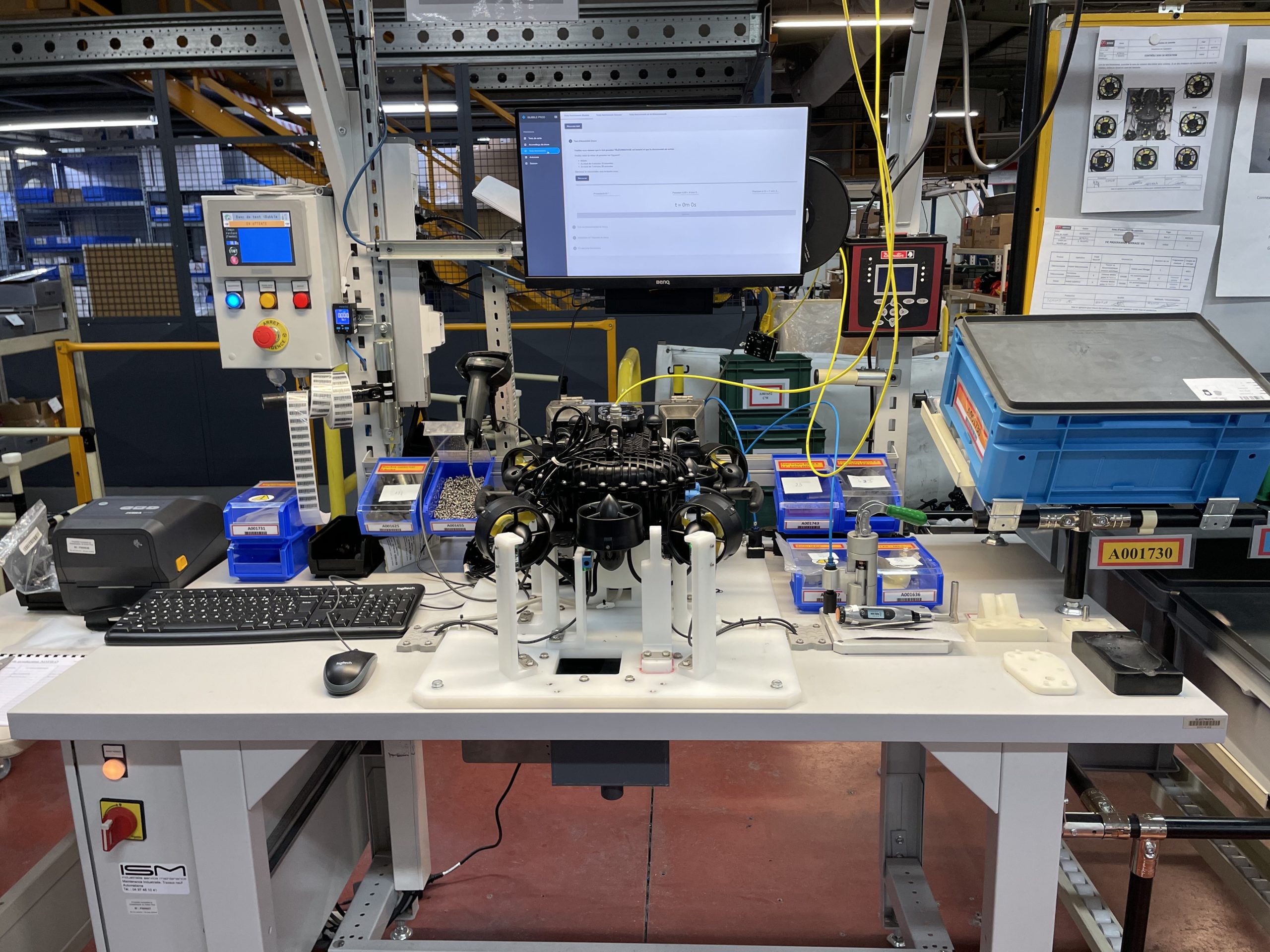

PALO IT est un cabinet international de conseil en innovation et l’un des leaders dans le domaine du développement logiciel. Fondée en 2009, l’entreprise française est aujourd’hui présente sur 4 continents et emploie près de 650 salariés. Dans le cadre d’un besoin émanant d’une grande maison de luxe (dont le nom doit rester confidentiel), les équipes de PALO IT ont développé une solution répondant à un besoin essentiel auquel sont confrontées les maisons du luxe : authentifier et tracer l’origine des produits.

Pour répondre à ce besoin, PALO IT a en effet démontré sa capacité à innover et de penser la solution dans sa globalité en proposant des solutions créatives à fort technicité et valeur ajoutée. Ce projet repose en effet sur une méthodologie de travail allant de l’exploration d’une idée au lancement de l’industrialisation avec EFI. Ce projet est ainsi passé par toutes les phases d’industrialisation que sont le prototypage et la validation de faisabilité, la conception et le design de la solution cible, la réalisation de plusieurs versions de pilotes, des tests sur le terrain, et l’amélioration du produit jusqu’à la validation de la solution finale.

Project milestones

September 2021

INITIAL CONTACT PHASE

The company contacted our teams through the Group’s industrial accelerator – Axandus.

February 2022

REDESIGN AND QUALIFICATION OF THE PRODUCT

The product requires some design adjustments in order to be industrialised more easily in conjunction with Axandus.

March 2022

PRODUCTION OF PROTOTYPES FOR TESTING BY THE CUSTOMER

The teams assembled around 30 prototypes in order to obtain feedback from the end customer.

From March 2022 to date

PRODUCTION OF PRE-PRODUCTION SYSTEMS FOR CERTIFICATION

The teams have assembled around twenty pre-series systems with the aim of obtaining several certifications (CE, etc.).

Our added value

Within the framework of this project, one of EFI Automotive Service’s first in the support of innovative companies, we were able to offer PALO IT our expertise in the following areas:

- Obtaining all the elements necessary for the international marketing of its product on behalf of the client, including the customs code and various certifications (CE, etc.).

- Acquiring valuable new skills for our teams in the course of this project, demonstrating that supporting innovative companies is a mutually beneficial exchange.

Key figures of the project

30

prototypes assembled by our teams

20

pre-production systems assembled by our teams

36

countries where the luxury house’s points of sale are located

85

systems ordered by the end of the year

Key figures of the project

30

prototypes assembled by our teams

20

pre-production systems assembled by our teams

36

countries where the luxury house’s points of sale are located

85

systems ordered by the end of the year

Are you interested in our support?

Do you have a project?

Safehear

THE HEARING PROTECTION OF THE FUTURE

Discover the collaboration between EFI Automotive Service and the French start-up Safehear.

The project and its context

The Safehear adventure began with the response to a constraint: to enable employees working in noisy environments (industrial sites) to communicate without latency and without risk of hearing loss. Héléna Jérome and Antoine Kuhnast, co-founders of the French start-up, hired partners from the major players in the in-ear market and research institutes to develop their solution. The outcome was a Made in France product named Louis; it is now promoted by a dynamic technical and commercial team.

The project in video

Project milestones

October 2021

INITIAL CONTACT PHASE

The start-up contacted our teams through the Group’s industrial accelerator – Axandus.

May 2022

PROTOTYPING

The teams start the design phase of the prototypes for the start-up.

September 2022

PROPOSAL OF SUPPORT FOR THE CONTINUATION OF THE PROJECT

Our teams have already proposed to the start-up to go further, by suggesting improvements for the second version of Louis.

Our added value

Within the framework of this project, one of EFI Automotive Service’s first in the support of innovative companies, we were able to offer Safehear our expertise in the following areas:

- Design and production of prototypes (80 planned by 2023)

- Provision of a 30 m² pressurised room allowing the teams to work in a controlled environment

KEY FIGURES OF THE PROJECT

20

prototypes made to date

100 dB

maximum sound volume in which Louis can operate effectively

29 dB

of maximum noise level reduction

10 h

of autonomy

15 m

maximum range between two users

30 gr

Louis’ weight

2

years of research and development to create Louis

3 h

required for a complete recharge

KEY FIGURES OF THE PROJECT

20

prototypes made to date

100 dB

maximum sound volume in which Louis can operate effectively

29 dB

of maximum noise level reduction

10 h

of autonomy

15 m

maximum range between two users

30 gr

Louis’ weight

2

years of research and development to create Louis

3 h

required for a complete recharge

Are you interested in our support?

Do you have a project?